| Colour | |

|---|---|

| Made in | |

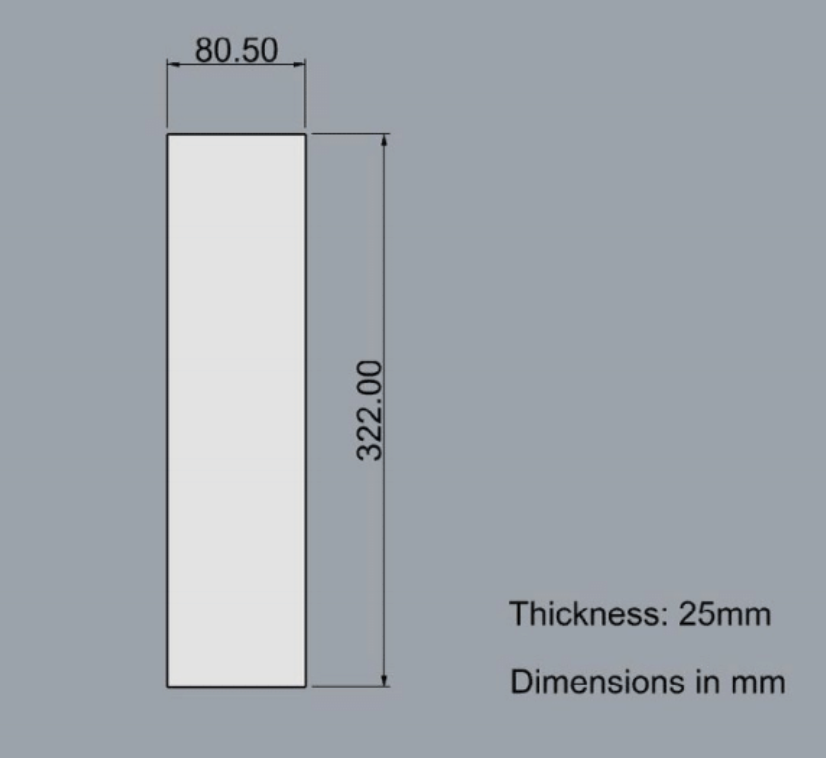

| Measurements | |

| Use | , |

| Sustainability |

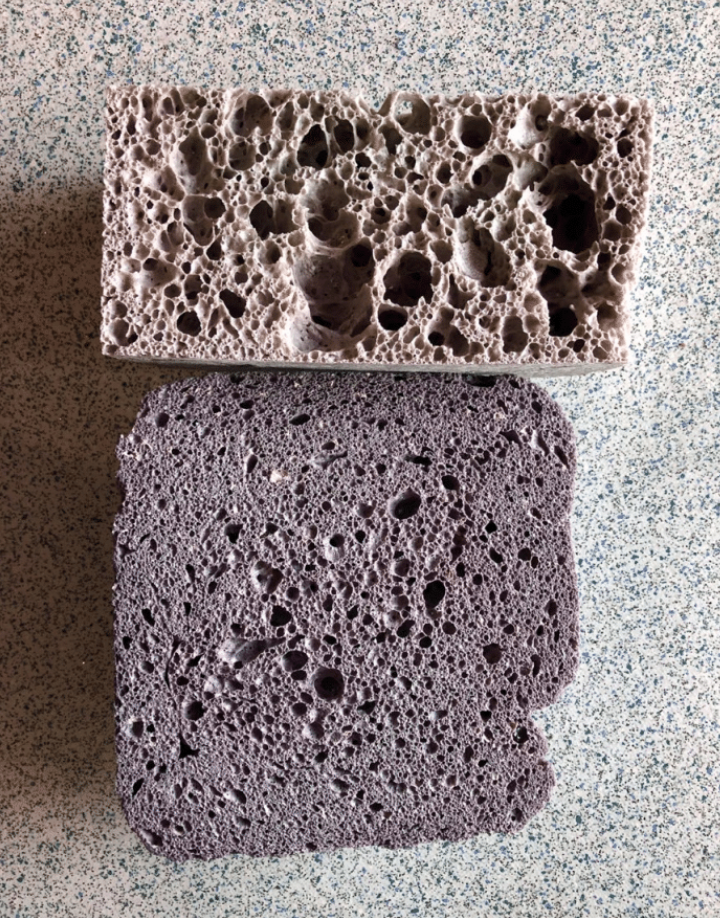

Glass Foam Tiles Grey/Pink

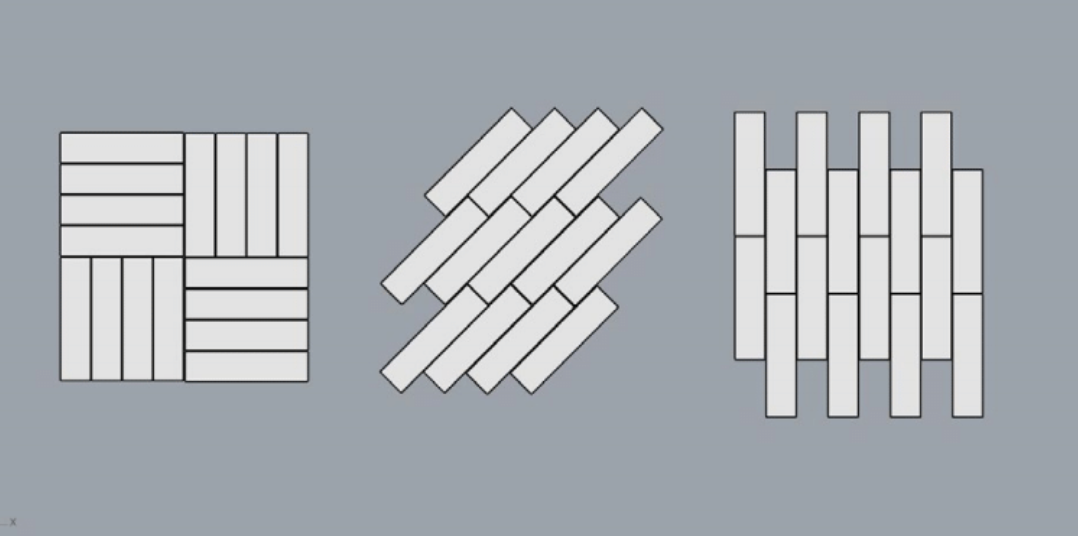

One of the amazing properties of glass foam is its sound insulation quality. In continuity of the SA100 tiles, this direction furthers the development of singular interior tiling.

These tiles could be a visually striking acoustic solution for noisy spaces like offices, retirement homes, restaurants…

Materials: recycled consumer glass and reclaimed eggshells.

Glass foam is partly crystallized and it becomes a sort of

ceramic. It is about 80% ceramic and 20% glass which means

that it would need an 80% addition of glass to make a new

glass foam batch.

Offcuts and discarded objects can be melted again in a mold at

around 950°C to make a single glass foam object that can then

be cut again in the desired shape. If heated even more,

the piece will become solid and devoid of cells (like a rock)

Glass foam can be shaped with a mold and by cutting-sculpting.

The mold is a bit like a cake mold and can have different

shapes depending on the bending and cutting of refractory

stainless steel. After unmolding the foam block, it can

be sliced with a band saw and carved with a dremel drill,

similarly to cellular concrete.

Sound: acoustic tests to determine the RW value of different

glass foams.

Fire: anti-fire testing.

Emissions: Air pollution emission tests.